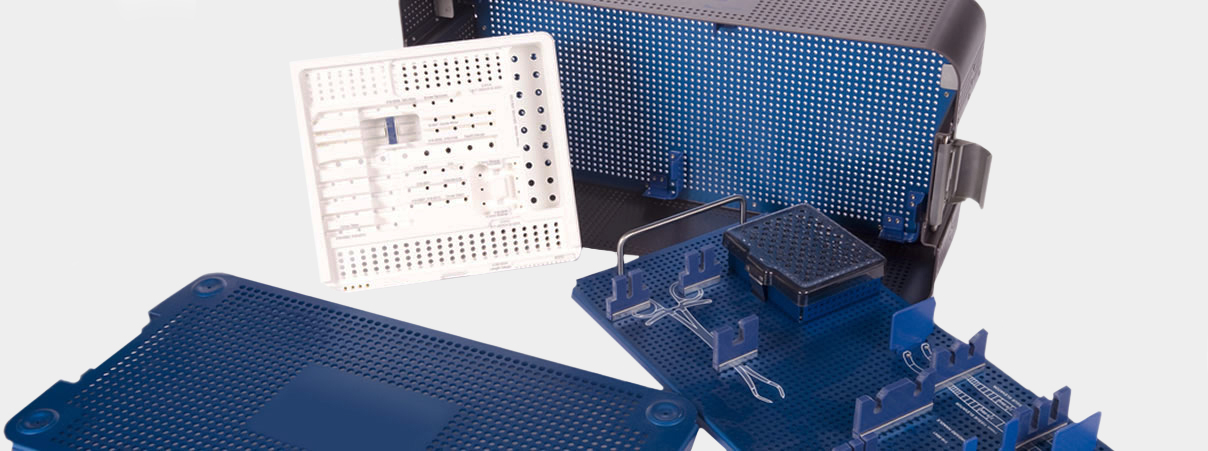

Effective, Efficient Instrument Cases and Trays

Avalign designs and manufactures metal and thermoformed medical instrument cases and trays with innovative versatility, short lead times, and on-time delivery.

Versatility

• More customization options

• Anodizing and nylon coating for sequencing

• More graphic and branding opportunities

Engineering

• Design and development consulting

• Innovation for better sterilization and reduced weight

• Custom and pre-made options

Delivery

• Short lead times

• Unmatched timelines for prototype and production

• Inventory management system to speed production and reduce costs

Cases and Trays for Any Application

We create customized and pre-made medical instrument cases and trays for any application. Our experienced team designs and develops cases and trays that help to meet operational goals and exceed quality and sterilization standards.

• Innovative hole configurations to reduce system weight

• Anodizing and nylon coating in custom colors for better sequencing

• Digital anodizing for graphic design and branding options

• Any production quantity from prototype to large launch

• Engineering expertise to improve look and function while reducing costs

How Our Process Works

Avalign uses a large, experienced design team to manage case development from beginning to end. We match standards and requirements, while also suggesting improvements, efficiencies, and savings that help deliver better quality results. We’re committed to short lead times and on-time delivery, regardless of quantity or complexity. Learn more about the facility that manufactures our cases.

Avalign Provides Better Cases in Less Time

From customization to quality improvements, Avalign ensures the best possible instrument cases and trays for any application. We leverage advanced knowledge and expertise to provide better functionality and safety, while shortening manufacturing timeframes and ensuring on-time delivery.

• We offer more design options to meet even the most specialized needs.

• We innovate to deliver better quality, performance, and safety in all of our cases and trays.

• Our inventory management and delivery timelines are unmatched in the medical device industry.

Learn how Avalign Delivery Systems can provide better and faster medical instrument case and tray products. Find an Avalign sales representative for more information and custom quotes.